Welcome to the age of smart warehouses, where even the shelves have an IQ higher than yours.

If your only exposure to warehouses is Hollywood, you’re probably thinking of a dark, echoey building filled with ominous crates labeled “TOP SECRET” or an IKEA-like labyrinth where people go in but never come out.

But real warehouses? They’re basically giant logistical puzzles — except instead of neatly placed puzzle pieces, you have forklifts doing donuts, barcode scanners beeping like overenthusiastic alarm clocks, and workers speed-walking like they’re late for a flight. It’s controlled chaos… until it’s not.

Enter Warehouse 4.0, where the Internet of Things (IoT) swoops in to turn these storage jungles into ultra-efficient, borderline sentient logistical masterminds. It’s like giving your warehouse a brain — one that never forgets, never misplaces things, and doesn’t get distracted by cat videos.

A Quick History of Warehouses and How We Got Here

Way back, warehouses were just glorified storage closets. Then came industrialization, conveyor belts, forklifts, and barcode scanners, and suddenly, warehouses started resembling sci-fi movie sets.

Fast forward to today, and thanks to IoT, we’ve reached the point where these buildings can think (or at least fake it pretty well). The magic word here is connectivity. Everything — shelves, scanners, robots, even the temperature — is linked up and chatting away like a group chat that never sleeps.

How IoT is Making Warehouses Smarter Than Your Average Human

IoT isn’t just about slapping sensors onto everything and hoping for the best. It’s about using those sensors to make warehouse life infinitely less frustrating. Here’s how:

1. Never Lose Anything Again With Real-Time Inventory Tracking

Have you ever lost your keys? Of course you have. Now imagine misplacing a shipment of $100,000 worth of electronics. Not ideal.

IoT fixes this with RFID tags and smart tracking that give every single item a digital ID. No more scavenger hunts. No more “I swear it was just here!” moments. Just instant, laser-precise tracking.

And because IoT constantly updates inventory, you no longer have to do those soul-crushing end-of-year stock checks. It’s all automated, saving countless hours and ensuring accuracy down to the last item.

2. Machines That See Trouble Coming So You Can Avoid It

Nobody likes surprise breakdowns. Not your car, not your phone, and certainly not a critical piece of warehouse machinery that decides to die right before the holiday rush.

IoT solves this with predictive maintenance — sensors track wear and tear, flagging potential issues before they turn into expensive, productivity-killing disasters. It’s like having a mechanic who can see the future.

And if that wasn’t cool enough, some warehouses are now using digital twins — virtual replicas of their real-world equipment that run endless simulations to predict failures before they even happen. Think of it as a crystal ball but for conveyor belts.

3. Smart Shelves That Play Tetris Better Than You Ever Could

Traditional warehouses waste an absurd amount of space.

Enter Modula VLM — smart vertical lift modules that use IoT to optimize storage. These shelves literally adjust themselves based on inventory needs, ensuring every square inch is used efficiently. Think of it as Tetris but with a PhD in logistics.

The coolest part? These storage systems don’t just optimize space — they also reduce human effort. Instead of warehouse workers manually searching for items, automated systems retrieve them in seconds, cutting down on errors, fatigue, and warehouse-induced existential crises.

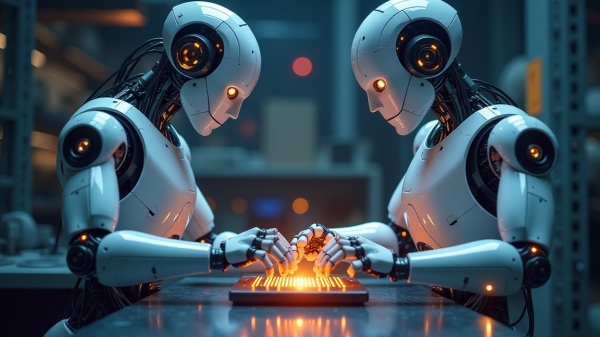

4. Robots That Don’t Need Coffee Breaks

You’ve seen those clips of Amazon’s warehouse robots scurrying around like hyper-focused Roombas? That’s IoT-powered Automated Guided Vehicles (AGVs) at work.

They don’t take lunch breaks. They don’t call in sick. They just move stuff fast — which is great for getting your next-day delivery actually delivered the next day. And then there are drones, casually flying around doing inventory checks because, well, we live in the future now.

But robots aren’t just about speed. They also enhance safety. Forklift-related accidents are a major warehouse hazard, and replacing human-driven equipment with AGVs can significantly reduce workplace injuries. Plus, fewer injuries mean fewer legal headaches.

5. The Supply Chain Crystal Ball

Warehouses aren’t islands — they’re part of a bigger, messier supply chain that is always one delay away from chaos. IoT helps warehouses anticipate problems, reroute shipments, and adjust stock levels before disaster strikes.

Example: A shipment of perishable goods is delayed. Instead of panicking, IoT-enabled refrigeration tweaks the temperature to prevent spoilage. Boom — crisis averted.

And the next level? AI-powered demand forecasting, which predicts which products will be in demand weeks or even months in advance, letting warehouses stock up before the rush hits. No more last-minute scrambling. No more “Why is every store out of toilet paper again?” moments.

But Wait, There’s a Catch

Of course, nothing this game-changing comes without a few “fun” challenges. IoT requires a solid upfront investment, cybersecurity that can keep out digital boogeymen, and a workforce that actually knows how to use the tech.

Also, it is not easy to convince old-school warehouse managers that robots and AI are here to help, not replace them. But once these systems are in place? They save time, money, and frustration.

There’s also the issue of data overload. With everything being tracked, optimized, and analyzed in real time, warehouses are drowning in data. Turning that data into actionable insights is a whole new challenge that companies are still figuring out.

Final Thought: The Future is Basically Now

Warehouses are no longer just giant buildings full of stuff. They’re turning into intelligent, hyper-efficient ecosystems that run smoother than your morning coffee routine.

And next time you order something online, and it magically appears on your doorstep within hours, just remember: behind that seamless delivery was a warehouse running on IoT, doing its thing with machine-level precision.

So yeah, warehouses are getting smarter. The only question is — when will the rest of us catch up? The answer? Hopefully soon, because if the shelves start outsmarting us, we’re in trouble.

The post Warehouse 4.0: The Role of IoT in Smart Warehousing appeared first on IoT Business News.